Wind turbine A-Z for your home, garden or business

What do terms and data mean in relation to small wind turbines?

Here you will find the answers using the example of an H 1000 Mini (column 3)!

| Accumulator = Battery storage = PV storage = Wind energy storage = Emergency power supplier | Batteries with the appropriate capacity and control are a good and efficient solution for reducing electricity costs. However, Energy storage systems currently in use for PV systems have a limited number of charging and discharging cycles. This number of cycles is usually 5000 – 6000 charging cycles. Extrapolated to one charge and discharge per day, this results in an expected battery service life of approx. 13.5 to 16.5 years. Using this storage system for the additional storage of electricity from wind turbines is therefore not a good solution, as the number of charging cycles for wind turbines is significantly higher than for PV systems. It can therefore be assumed that coupled wind turbines would significantly shorten the service life of PV batteries! LFP Energy storage systems with over 12000 charging cycles are now available. These can also be used with PV coupled with wind power without any problems. In combination with a 380V inverter with emergency power capability, this is the ideal solution for every household and small business! Alternatively, we recommend separate storage in wet batteries (lead batteries = truck batteries) with an unlimited number of cycles or direct feed-in to the domestic grid via 3-phase or 3 single-phase inverters. This coupled with a smart meter, i.e. intelligent feed-in/draw-off current monitoring, can be considerably more effective than storage. | for information only |

| Aneometer | Measuring device for wind speed. Suitable as a hand-held device for measuring wind speed, e.g. at your desired location. However, it is also an optional addition to a good wind controller as a system device. This can be used to trigger braking in the event of cut-out wind or to stop the turbine at the maximum permissible wind speed! | optionally available |

| Registration (with the network operator) | To successfully register a wind turbine with your grid operator, at least the following proof is required: + certificate for grid and system protection + unit certificate + technical data sheet for the inverter Required for all grid-connected systems without exception! see also “plug-in systems” | is supplied by us! |

| Number of rotor blades | The more blades, the smoother and quieter the wind turbine should be. Wind turbines with 2 blades are therefore not recommended in our opinion. (We know from a nearby user that a 2-bladed wind turbine made in Germany could be heard at wind speeds of 6 Bft (approx. 40km/h = strong wind) even at a distance of 300m and that the whole roof truss vibrated! This wind turbine was deshalb dismantled again in the meantime). However, too many rotor blades can also have a negative effect, as a rotor blade that follows at too close a distance becomes ineffective in the turbulence of the rotor blade turning in front of it! | 5 pieces |

| Working temperature | Important for permanent year-round operation, should therefore suit your location! | -20°C to +50°C |

| Output voltage <- > Input voltage (from turbine or generator to inverter) | You can use the 3-phase AC output voltage of the wind turbine (generator) to calculate what DC input voltage the downstream inverter should have. The formula is Vac = Vdc / 1.732 or Vdc = Vac * 1.732 For example, if the AC output range of the generator is 26-52 V, the DC input voltage range of the inverter should be 45V-90 V. 26V*1.732 = 45V 52V*1.732 = 90V | for your information! |

| Design period | For what operating times are the components dimensioned (for normal operation and short-term maximum load)? Decisive for the service life of a wind turbine! | 25 years |

| Degree of self-sufficiency | The degree of self-sufficiency indicates what percentage of a household’s own energy requirements is covered by self-generated energy without drawing additional energy from the public grid. For example: If a household has 100 % of its energy requirements and 70 % of these are covered by its own wind turbine, the degree of self-sufficiency is 70 %. This means that 30% of the electricity still has to be drawn from the public grid. A higher degree of self-sufficiency means greater independence from external energy sources and a higher level of self-sufficiency with renewable energy. | for information only |

| Battery storage capacity | see calculation | |

| Design = Wind turbine type | H with horizontal axis -> classic design, see HAWT V with vertical axis -> modern design, see VAWT Darrieus rotor, see Darrieus Savonius rotor, see Savonius | Example H 1000 Mini |

| Beaufort scale | The Beaufort wind scale can be used to get a feeling for the wind prevailing at the planned location. We have outlined the operating range of small wind turbines in red in our Beaufort table. In our experience, investing in small wind turbines only pays off from an average wind force of 3 upwards! | for information only |

| Calculation -> Battery storage capacity in kWh | Multiply battery voltage (V) by battery capacity (Ah) and number of batteries! For example, 2 12V lead/acid car batteries with 80Ah each (only 50% usable with wet batteries due to undervoltage protection) 12V * 80Ah * 2 * 0.5 = 960W = 0.96 kW | for information only |

| Calculation / Conversion -> Speed m/s to km/h | multiply m/s by 3.6 ! m/s * 3.6 = km/h | for information only |

| Calculation -> Peripheral speed | Multiply rotor diameter (in meters) by Pi and speed (in rpm = RPM) per second (minute /60). Example H1000 Mini with rotation limit: 2m * 3.14 * 750 rpm / 60 = 78.5 m/s = 282.6 km/h | 282.6 km/h |

| Operating voltage e.g. 12V/24V or 24V/48V or 12-96V | For small wind turbines, voltages are usually used that also allow storage in batteries. The generators usually allow different operating voltages. For example, a 12V/24V generator (with 2 12V batteries connected in series) could deliver twice the power at 24V compared to 12V, but the rotor does not become larger by increasing the voltage and therefore cannot develop more power! In real terms, the current (A) is therefore halved – > The actual power output remains the same! A power rating of e.g. 300W/600W (at 12V/24V) is therefore misleading! Adjustable devices are therefore also more of a dazzle! | 12V/24V |

| Brake unit | Should be electrical (dump load) or mechanical/hydraulic. “Stall” means stall, stresses the components and is always associated with increased noise! | electric |

| Controller (charge controller) = rectifier + turbine monitoring + optimization | AC to DC conversion: Converts the alternating current produced by the generator into direct current. Good devices monitor the wind speed (e.g. using an external aneometer), rotor speed, power output of the generator and wind direction (not required for vertical rotors) and adjusts the power output to the battery or inverter. In this way, the controller ensures that the wind turbine generates the correct power at all times and can be switched off in the event of an overload. Some manufacturers only offer rectifiers instead of a controller. These have no monitoring or optimization function and are therefore not a good and permanent solution! Power optimization: Good devices ensure that the maximum power of the system is used by determining(tracking) and maintaining the maximum power point(MPP). | optionally available |

| Cut-In Wind | Wind speed at which the wind turbine starts to produce -> the lower the better | 2.5 m/s = 9 km/h |

| Cut-out wind | Wind speed above which the generator and/or controller can be overloaded and the wind turbine should be braked | 25 m/s = 90 km/h |

| Darrieu’s rotor | A Darrieus rotor is a wind turbine with a vertical axis of rotation (VAWT, vertical axis wind turbine). This type of rotor has the advantage that it can operate independently of the wind direction. Depending on the current blade position, Darrieus rotors do not start on their own and require a separate drive to get moving. For this reason, many of these rotor blades have a so-called push-off aid on the back (e.g. protrusions). Darrieu’s rotors work aerodynamically, like an airplane wing, are virtually pulled by the wind and can become extremely fast. They should therefore be braked from a (limit) speed. | n. A. |

| Dump load | Dump load (also known as diversion load or dummy load) is an important component in the control of small wind turbines. On the one hand, it is used to divert excess energy when the batteries in an off-grid system are full and cannot absorb any more energy. Another function is to brake the turbine when the cut-out wind speed is reached. In such systems, the excess electrical energy that can no longer be stored or that is used for braking is diverted to an external load such as a heating resistor. This prevents the wind turbine or generator from being overloaded and protects the system from damage | part of the controller for our products |

| Input voltage <- > Output voltage | see output voltage | |

| Unit certificate | for inverters or controller/inverter combination devices: In accordance with: VDE-AR-N 4105: 2018-11 + Revision 1: 2020-10 “Generation plants on the low-voltage grid” And in accordance with: DIN VDE V 0124-100 (VDE V 0124-100): 2020-06 “Grid integration of generation systems” Must be submitted to the grid operator when registering the system! | is always supplied by us! |

| Feed-in voltage 230V NPE 1-phase 380V N3PE 3-phase | Grid-connected devices (including PV inverters) up to 3000W = 3KW are usually connected to the in-house grid with 230V single-phase (NPE with Schuko or Wieland plug). But is there also a (continuous) load connected to this one of 3 possible phases or do you give your grid operator electricity for 8.4ct/kW? With a 3-phase feed-in, you can always be sure that all consumers are supplied and thus a maximum of electricity is consumed (useful from 1kW)! | 230V/50Hz NPE (Var. 3) |

| Generator | (Wind) generators convert the kinetic energy (rotation) of the rotor into electrical energy (alternating current). This energy can either be used directly, stored or fed into the power grid. Insist on three-phase permanent magnets (DPM or PMG). These are optimized for power generation. Reversely switched electric motors or stepper motors are often part of cheap solutions and are not a good solution for wind turbines! Please note: A generator can only deliver the maximum power that the rotor can absorb from the wind! The rotor power (kinetic energy) depends on the rotor area (–> power absorption) and rotor diameter (–> torque)(see here)! If, for example, 300/600V is specified as the generator output, this is misleading. See also operating voltage! | Three-phase permanent magnet (DPM) |

| Generator efficiency | What percentage of electrical power does the generator produce from the mechanical = kinetic power (rotation) of the wind turbine? | > 85 % |

| HAWT | Horizontalaxis wind turbine, the rotor axis is horizontal | Yes |

| Manufacturer’s warranty | Shows you how much confidence a manufacturer has in its products! | 5 years on our wind turbines |

| Inverter = Grid feeder + grid monitoring + optimization | Inverters have several tasks: Conversion from DC to AC: Converts the direct current supplied by the controller or the battery back into (mains) alternating current, which can be used in the household or fed into the power grid. Safety and monitoring: Inverters monitor the power grid, adapt to the grid frequency and disconnect the system in the event of faults to prevent damage. Power optimization: Good devices ensure that the maximum power of the system is used by determining(tracking) and maintaining the maximum power point(MPP). Note: To avoid premature destruction, pay particular attention to the input voltage and maximum power that can be absorbed by the inverter! If necessary, it is better to select the next higher power level! | optionally available |

| Annual output, expected | The theoretical calculation of the possible output (kWh/a) per year (per annum) of a wind turbine, using Rayleigh wind distribution, based on the average wind speed prevailing at the location, taking into account the power curve of the wind turbine. This information can be used to estimate the savings per year, for example. It is therefore an important part of the amortization calculation! However, also take the degree of self-sufficiency into account when calculating the amortization (see above)! | e.g. on the Wurster North Sea coast average wind 6.5m/s -> 2058 kWh/a |

| Components (of a wind turbine) | A wind turbine basically consists of the following main elements: 1) Rotor 2) Generator 3h) Wind direction unit(for horizontal rotors) 3v) Pushing aid (for vertical rotors) 4) Braking unit 5) Mast or tower 6) Rectifier (usually integrated in 6) 7) Charge controller 8) Inverter | |

| Charge controller(controller) | see Controller | |

| Volume / noise level | If necessary, also pay attention to information such as …from xxxUpM sound velocity at the blade tip or “stall” (-> do not buy). Details on the permitted noise level can be found here! | <40 dBA (see curve for product) |

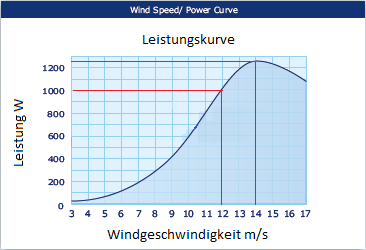

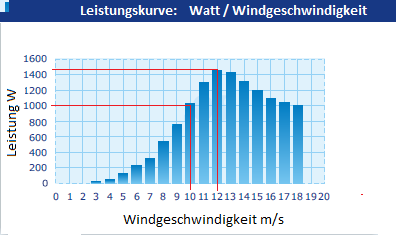

| Power curve | The graphical representation of the turbine output (kW) as a function of the wind speed (m/s or km/h) or the rotor speed (rpm). With a good manufacturer, this is part of the product description! The power curve also serves as the basis for setting the optimum MPPT data sets! | |

| Maximum permissible wind / destructive wind speed | Wind speed above which the wind turbine can be destroyed -> the higher the better | 50 m/s = 180 km/h |

| MPPT(curve or data records) | MPPTstands for Maximum Power Point Tracking. It is a technology used in photovoltaic and wind power systems to maximize the energy yield. An MPPT controller continuously adjusts the electrical load on the solar cells or wind generator so that the maximum power can always be drawn. This is particularly important as the optimum operating point of the generator depends on the factors of speed and temperature. Essentially, an MPPT controller functions as a DC-to-DC converter that adjusts the voltage and current of the generator/solar modules so that the maximum output is achieved. This increases the efficiency of the entire system! The power curve of the generator used serves as the basis for optimum MPPT data sets! | a component of our controller The MPPT data sets of our wind turbines are preset in the controllers or controllers/inverters supplied by us ! |

| NA protection certificate | see: Certificate for network and system protection | is always supplied by us! |

| Rated power | Electrical power that a wind turbine produces at nominal speed regardless of the operating voltage and can feed into the grid if necessary. For example, if a wind turbine produces 1000W = 1kW for 1 hour, this results in a kilowatt-hour 1 kWh. You would pay your electricity supplier e.g. 35ct/kWh for this. With the nominal output and the average wind speed at the installation site, you can estimate an expected annual output using the Rayleigh wind distribution (see Rayleigh wind distribution or annual output)! | 1000 W (see power curve below)! |

| Nominal wind speed | Wind speed at which the wind turbine generates the rated power (see power curve below) -> the lower the better | 12 m/s = 43 km/h |

| Emergency power supply | Many users are unaware that PV inverters require feedback from the grid in order to feed in electricity. This means that in the event of a power failure, the inverters also switch off and produce no electricity. In the event of a power failure, there is no electricity in the household despite PV! We can now supply you with inverters that automatically switch to “island operation” in the event of a power failure, i.e. produce pure sinusoidal electricity that continues to supply your household with electricity. Paired with a large Energy storage system and/or PV and/or wind energy, this 3-phase inverter can also continue to operate all your appliances! | to the info |

| Off-grid (independent of the grid) | Off-grid means “not connected to the (electricity) grid”. In other words, a power generation system that cannot feed into your home grid (the utility grid). | optionally possible |

| On-grid (connected to the public grid) | On-grid means “connected to the (electricity) grid”. In other words, a power generation system that picks up the grid frequency (of your home grid or the supplier’s grid) and adjusts the frequency of the electricity to be supplied to it and can therefore feed the storm into the grid. | optionally possible |

| Parallel connection (mostly for batteries) | If batteries are connected in parallel (+an+/-an-), the operating voltage remains the same. Two 12V batteries in parallel result in 12V. The capacity increases (in this case doubles). Alternatively, see series connection! | for information only |

| Rayleigh wind distribution | It is often used to calculate the yield (e.g. in kilowatt hours per year = per anno -> kWh/a) of wind turbines. It is a mathematical probability function, a special form of the Weibull distribution, which is often used to describe the wind speed distribution at a location if no long-term wind measurements are available. The distribution of 10-minute mean wind speed values is usually used. The wind speed according to the wind map of the DWD, Offenbach can be used as the base value. | see annual output |

| Series connection (mostly for batteries) | If batteries are connected in series (+to-), the operating voltage increases. Two 12V batteries in series result in 24V. Alternatively, see parallel connection! | just for info |

| pure sine wave | The inverter converts the direct current DC into alternating current AC. The alternating current is output in a sinusoidal wave. In this context, a pure sine wave means that the inverter does not pick up any mains frequency (i.e. works off-grid) and must therefore not be connected to the mains supply! These devices can be used, for example, to operate a small and independent power grid in the garden shed. | optionally possible |

| Rotation limit | Speed at which the wind turbine must be braked (e.g. electrically by “dump load” or hydraulically with disk brake) | 750 rpm (revolutions per minute) |

| Rotor | Wind rotors absorb the kinetic energy of the wind and convert it into a rotary motion. This energy is used to drive a generator. The larger the rotor, or the larger its effective effective area, the greater the energy that can be absorbed! Also consider suitable corrosion protection if a material other than GRP is specified! Please also note that high-speed rotors (depending on the number of blades, diameter and design) should bebalanced. Otherwise they will cause vibrations that can shake the entire roof truss. | GRP, factory-balanced! |

| Rotor blade skew | Vertical wind turbines are also available with an inclined or tangential twist. On the one hand, this ensures that one rotor blade is always in the wind (as a replacement for the pushing aid) and that the wind turbine is constantly working under load, i.e. is not subjected to pulsating loads when turning as can be the case with simply vertical rotors (e.g. 3 times for each turn with 3 rotor blades). As a negative side effect, however, these wind turbines have a vertical load component that constantly loads the rotor up and down. In most cases, this leads to vertical vibrations that have to be compensated for by a compensator. The installation of such a wind turbine on a house roof is therefore not recommended in our opinion! | to the info |

| Rotor diameter | The larger the diameter, the greater the torque of the rotor and the lower the speed can/should be. For optimum electricity production, the rotor and generator must be matched to each other. With a large rotor diameter, generators with an equally large diameter and low required speed are required. Narrow generators or inversely connected electric motors for high speeds are then unsuitable (unless a gearbox is connected in between, in which case the power is reduced by the transmission factor). | 2 m |

| Savonius rotor | A Savonius rotor is also a wind turbine with a vertical axis of rotation (VAWT, Vertical Axis Wind Turbine). The rotor consists of two or more blade-shaped vanes that are mounted vertically. Savonius rotors are so-called drag rotors, in which one side of a rotor blade offers greater resistance to the wind than the opposite side. The wind therefore pushes the rotor, setting it in motion. The maximum circumferential speed therefore corresponds to the respective wind speed. However, as the air resistance of the opposite side increases (by the square) with increasing speed, such rotors eventually reach a rotational speed at which the front and rear sides have the same air resistance. The rotor can no longer speed up due to the force equalization. This means that the rotor reaches its limit circumferential wind speed (speed x circumference), which is therefore below the wind speed. High-speed generators are therefore unsuitable. | n. A. |

| Apparent power VA | The apparent power VA is the total energy that an appliance can emit. However, the efficiency of an appliance (e.g. 95%) must be taken into account here. This must be taken into account when determining the active power W (actual usable power). So that, for example, with 800VA and 95% efficiency, only 760W actually result. However, we neglect this on our site and therefore write in VA(≈W) | |

| Top performance | maximum power of a wind turbine (see power curve below) -> the higher the better | 1250 W |

| Stable | Stall (or stall) is a term used in aviation. It refers to the condition in which the wings of an aircraft can no longer generate enough lift to keep the aircraft in the air. This happens when the angle of attack of the wings becomes too great and the airflow over the wings breaks off. In the case of wind turbines, this means that the rotor blades bend so much that they can no longer generate propulsion. | n. A. |

| Start wind | Wind speed at which the wind turbine starts = begins to rotate but is not yet producing -> the lower the better | 1.5 – 2m/s = 5-7km/h |

| Plug-in systems | The regulations of VDE-AR-N 4105 allow consumers to install their own mini systems for private electricity generation up to a maximum total output of 800 watts – under defined conditions – and to register them with the grid operator and in the BNetzA’s market master data register. Registration with the grid operator up to this maximum output is no longer mandatory, unless you wish to be paid for the electricity fed into the grid. Then this registration is also required! An electrician is recommended, but currently not required up to 600W; for more than 600W, the system must be connected by a specialist electrical company! See also Wind turbine legal information | 1000> 800W , therefore this device must be registered! |

| Turbine weight | Too light -> poor quality / too heavy -> reduced performance due to increased energy consumption -> admittedly difficult to evaluate! | 27 kg (incl. generator) |

| Peripheral speed of the rotor | see calculations | for your information! |

| VAWT | Verticalaxis wind turbine, the rotor axis is vertical | no |

| WEA | Official abbreviation for wind energy plant | for info only |

| Inverter | see inverter | Yes |

| Wind direction | Vertical wind turbines are (almost) independent of the wind due to their design. Depending on the current blade position, aerodynamic wind turbines (high-speed turbines) do not start on their own and require a short push to get moving. For this reason, many such rotor blades have a so-called push aid on the back (e.g. protrusions). The position of the rotor blades does not matter for blade-shaped resistance rotors. They start from any position. Horizontal wind turbines must be kept in the wind! This is done with large wind turbines by measuring the wind direction and an electrical tracking system (with motor). For small wind turbines, a vertical stabilizer (wind vane) is usually used. | Equipped with vertical stabilizer |

| Certificates | Make sure that you have all the necessary certificates. This applies to the wind turbine, controller and inverter! Certain certificates are mandatory when registering a system with the grid operator! | CE, RoHS, ETL, ISO 9001:2008, ISO 14001 unit certificate, NA protection certificate |

| Certificate for grid and system protection (NA protection certificate) | for inverters or controller/inverter combination devices: In accordance with: VDE-AR-N 4105: 2018-11 + Revision 1: 2020-10 “Generation systems on the low-voltage grid” and in accordance with: DIN VDE V 0124-100 (VDE V 0124-100): 2020-06 “Grid integration of generation systems” Must be submitted when registering the system with the grid operator! | is always supplied by us! |